SCANVAEGT ABWL SYSTEM

SCANVAEGT ABWL SYSTEM

Ensuring Correctly Labeled Cartons with Correct Weight Content

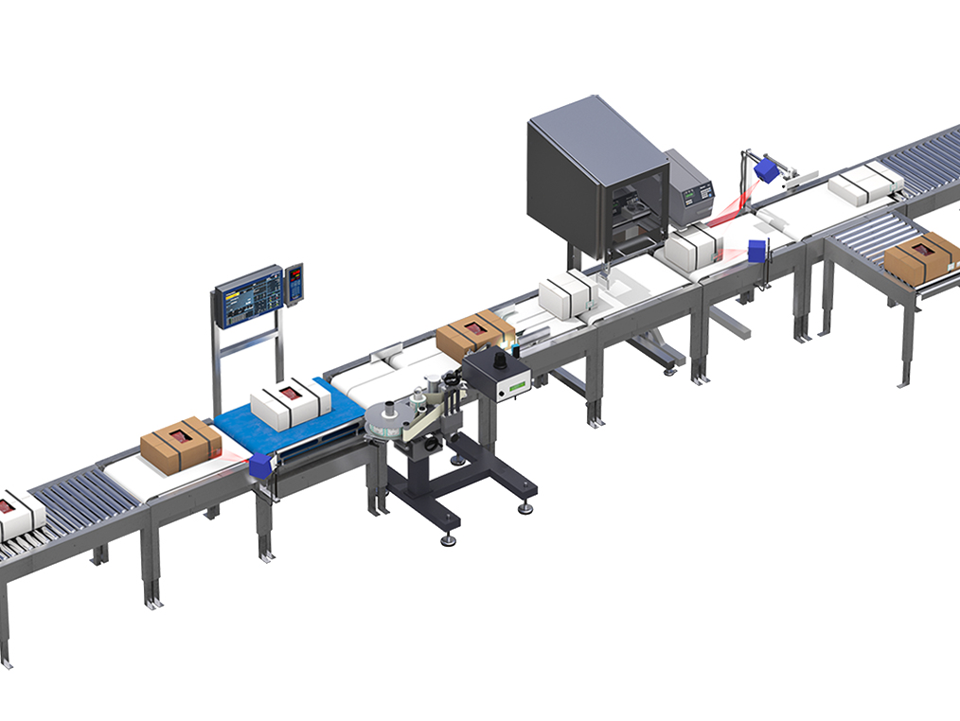

The Scanvaegt ABWL System weighs and labels the carton while simultaneously verifying that both the weight content and the information on the label are correct, that the EU label is properly placed, and that the barcode is readable.

When cartons need to be packed, sealed, weighed, and labeled, there is a risk of errors. These errors can vary; the weight content might be incorrect, the barcode might be unreadable, the EU label might be placed incorrectly, or there may be discrepancies between the contents and the label.

Such errors can be avoided with the Scanvaegt ABWL System, which – in addition to weighing and labeling the carton – simultaneously ensures that both the weight content and the information on the label are correct, that the EU label is placed correctly, and that the barcode is clear and readable. If the carton deviates from the specifications, it is sorted out and sent to a fault lane for possible repacking.

- Simultaneous control of both weight content and label information

- Flexible design with multiple label placement options

- Error elimination

- High application speed

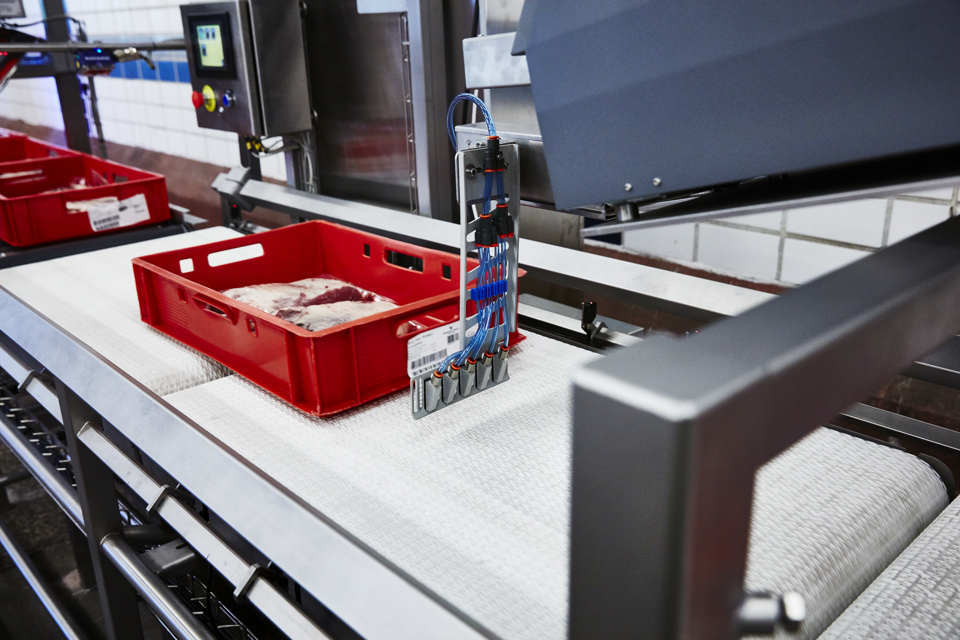

Integrated Control Functions Eliminate Errors When the carton is strapped, the EU label is applied over the strap and subsequently checked by a color scanner. The ABWL system has a stop function that ensures only one carton is on the scale at a time, preventing incorrect weight measurements. Once the carton is weighed, the weighing terminal connects the weight with order information retrieved from the company’s own IT system.

The carton is then sent to the labeling function, where weight and order information are printed on the label, which is automatically applied to the side or end of the carton. The information to be printed and the label layout can be freely defined. A scanner then reads the barcode on the label and verifies that it is readable and matches the data generated in the weighing terminal when registering on the scale.

One System with Many Functions The new weighing and labeling station consists of:

- Label applicator for applying the EU label

- Color scanner to check proper application of the EU label

- Belt scale for weighing the carton and weighing terminal for weight registration and communication with the IT system

- Conveyor with centering unit to align the carton in position

- Label printer in a steel cabinet and label applicator

- Scanner for post-checking customer label and carton

Flexible Label Applicators The ABWL system’s label applicators, developed by Scanvaegt Systems, have a flexible design, offering several options for label placement on package units. The label can be placed on the side of the carton, on the front end or back end, on the top of the carton, or over the carton’s edge. The applicators can also label cartons of different sizes simultaneously.

The label applicators do not require much space between the cartons – this, combined with their high application speed, allows them to handle up to 20 cartons per minute for cartons with variable weight and up to 40 cartons per minute for cartons with fixed weight.

Contact our specialists

International Business Manager - Food Industry

Automatic weighing systems

+45 4053 4900

Get a non-binding offer

Send us an email – we can help you move forward.