Damifo digitalises processes and improves operations.

Case Story: Damifo A/S

Damifo A/S specialises in the recycling of construction materials and strives to ensure that as much construction waste as possible is repurposed for useful applications rather than ending up in landfill.

Damifo / Dansk Miljøforbedring operates branches in Hedehusene, Rødby, and Vojens, receiving materials from the construction and civil engineering sectors that represent potential resources. The company ensures these materials are handled efficiently and in an environmentally responsible manner.

Among the materials received are asphalt, mixed waste, concrete, bio-ash/incineration slag, aerated concrete and gypsum, soil, bricks, and various types of wood. After sorting and processing, the materials are sold as, for example, crushed asphalt, recycled base course, crushed concrete, recycled ballast, topsoil, and wood chips.

Upon receipt, all materials are weighed on a weighbridge and registered with data such as weight, type/fraction, supplier, haulier/truck operator, agreement number, and other details required for invoicing, inventory management, resale, and reporting to the Danish Environmental Protection Agency.

Efficient Registration Process

With up to 160 vehicles needing to be weighed in and out daily, operations can be very busy, so weighing and registration must be carried out efficiently to avoid delays and long queues.

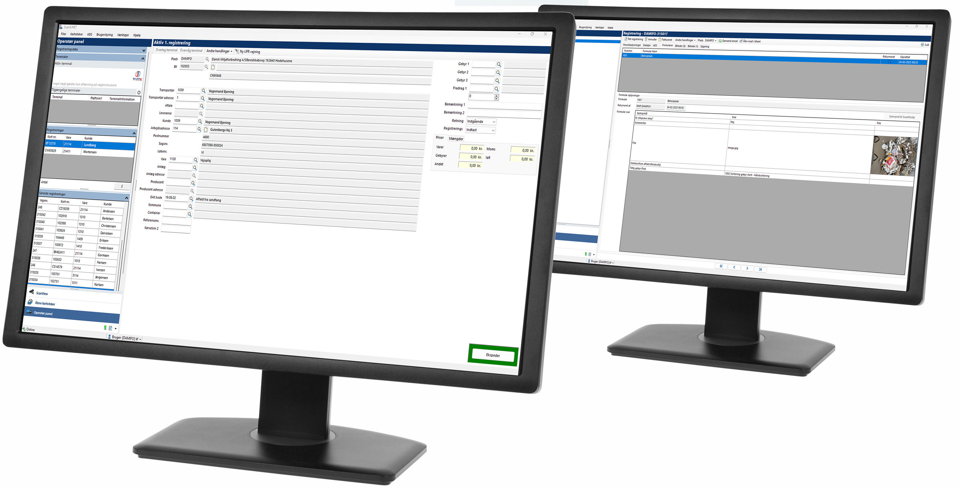

Today, Damifo handles this task using the ScanX.NET software solution, which was implemented in the spring of 2021. The solution consists of the core module along with several add-on modules, including those for managing multiple geographical sites, importing/exporting data, email reporting, camera surveillance, and photo documentation. The software system is scalable and can be expanded with additional modules as needed.

The system is easy to work with, and the registration process has become faster. Additionally, we have gained greater data security to ensure accurate records.

Project Manager, Damifo A/S

Easier, Faster, and Better Overview

Project Manager Kenneth Frederiksen has led the implementation of the ScanX.NET solution and is responsible for ensuring that daily operations run smoothly and continuously improve. He is very satisfied with the system and has experienced several improvements, which he explains:

“I generally find the system easy to work with, and the registration process has become faster. The entire soil and contract management program has made the work much easier than before. Additionally, we have achieved greater data security for accurate registrations.”

He continues:

“I am especially pleased with the management of contract numbers — it has given us complete oversight and control. I am currently working on the delivery program, which includes various materials and quantities. Here, I can create different delivery types under the same contract number, for example, if soil comes from the same site or if a construction site delivers both wood and waste, these can be grouped under the same contract number. When I need to generate a report of what a truck has carried, I can simply extract data by the contract number.”

Management of Multiple Geographical Locations

With the ScanX.NET module Facility Control, Damifo can manage its other branches, collect data, and provide support. Kenneth explains:

“Everything runs on the same SQL database, so all data is transferred to us. Our branch in Rødby can connect to us here in Hedehusene, where we can support them directly and, for example, guide drivers to the correct weighbridge terminal and explain how the process works. We can also ‘remotely operate’ the terminal and click the right buttons on behalf of the driver.”

Digitalisation Prevents Errors and Saves Time

Damifo also uses the LPR module, which automatically identifies trucks by license plate scanning when they weigh in and out on the weighbridge. This offers several advantages, Kenneth explains:

“The scanning happens quickly, so the driver saves time. We also avoid worn plastic or ID cards that can’t be read by the weighing terminal and therefore cause errors.”

With Facility Control, our branch in Rødby can connect to us here in Hedehusene, where we can guide drivers to the correct weighbridge terminal and explain how the process works.

Project Manager, Damifo A/S

Continuously Scaling the System

Kenneth is constantly striving to improve operations and leverage the ScanX.NET solution to ensure accurate data and save working time. Damifo has recently implemented two additional ScanX.NET modules — ADS/Waste Data System and Delivery Inspection for incoming inspection. Explaining the reason, Kenneth says:

“We need to report the many waste fractions to the authorities, and here we have chosen to implement the ADS/Waste Data System. It records the type of waste on both incoming and outgoing vehicles, which is stored in the database and ensures reporting to the Danish Environmental Protection Agency.”

With the other module, Delivery Inspection, Damifo easily carries out mandatory incoming inspections during the weighing of waste fractions, records deviations from declared waste fractions with photo documentation, and weighs the vehicle out.

Future Initiatives

Kenneth Frederiksen shares several ideas for new initiatives with the ScanX.NET system:

“We would like to establish a central weigh-in station here in Hedehusene so that all weighing can be done in the same location. We can achieve this with Facility Control, where we can log into the individual sites.”

When asked about their experience with ScanX.NET, Kenneth states:

“Everything has improved — the system itself is much faster than the old one we had. Everything is easier — from shortcuts to various functions, it is logical to navigate. And we have great support from Peter Jensen at Scanvaegt, who is always willing to explore new possibilities and provide valuable tips for setting up, among other things, user management.”

Damifo A/S currently uses a large portion of the software modules in the ScanX.NET package along with several hardware solutions, including:

- ScanX.NET Facility Control

- ScanX.NET Weighing Clients

- ScanX.NET Traffic Lights

- ScanX.NET E-mail Standard

- ScanX.NET Image Capture

- ScanX.NET Surveillance

- ScanX.NET Import/Export

- LPR Automatic License Plate Recognition

- VT200 Terminals

- Traffic lights for controlling weighbridge traffic

The advantage of the Scanvaegt systems is that the solution can be continuously expanded and scaled with new software modules and hardware products as needed.

Read more about the related products here:

Contact our heavy duty experts

International Business Manager - Weighbridges

Sweden, Norway, Finland

+46 (0)70 630 54 60

Have a question? Request a callback