Freiberg Group Saves Time and Improves Production Figures

Case Story: Freiberg Group

Freiberg Quarry loads up to 300 trucks with as much as 11,000 tons in a single day!Therefore, it is crucial for them to be able to quickly register the many trucks along with the weight of the delivered raw materials.

Freiberg Group, headquartered in Tønder, undertakes construction work, operates a transport company, and manages three quarries located in Rødekro, Uge, and Visby in Southern Jutland. They produce a range of materials including washed gravel, concrete gravel, asphalt gravel, crushed stone, road materials, and concrete mixes, and also sell Norwegian granite stones in all sizes. The total annual production can reach up to 700,000 tons.

At the Rødekro quarry, four wheel loaders handle the delivery of 25–30 different types of raw materials. Traffic volume varies, but on a busy summer day, up to 300 trucks may arrive, collectively loaded with up to 11,000 tons — all within a single day! Therefore, it is essential to quickly register the many trucks coming in and out, along with the weight of the raw materials delivered.

Need for a More Efficient Registration System

The heavy truck traffic demands an efficient registration system to keep track of customer data, goods, and delivered quantities. The process must be fast and error-free, without time-consuming manual interventions.

Freiberg already had a registration system in place, but it did not function optimally. The system frequently experienced downtime, and sometimes the software would freeze, requiring manual restarts, which resulted in significant lost work time. Drivers also complained about delays, as they needed to adhere to strict schedules.

Consequently, Managing Director Helmut Callesen decided to explore the market for an efficient registration system for the quarries in Rødekro and Uge. He outlined several key requirements for the system, including that it should:

- Be reliable to avoid downtime and wasted work hours

- Be internet-based, enabling easy data access from the head office down to the wheel loader operator in the quarry

- Be accessible online via tablets or smartphones, allowing operators to easily access the system, correct previously entered data, and input new data

- Be flexible and open, allowing all trucks to be processed — even without prior registration

- Allow multiple operators in the quarry to use the system simultaneously

- Be user-friendly so that foreign and new drivers could operate it easily

After market research, Helmut Callesen connected with Scanvaegt, who proposed the ScanLoader system as a solution for the quarries in both Rødekro and Uge.

Challenge

- Frequent system crashes requiring time-consuming restarts

- Only one operator could use the system at a time

- Lack of data access for all users—both at the gravel pit and in administration

- Waiting times for drivers and wasted time for operators

Solution

- Reliable system setup with a robust database solution

- Open, flexible solution with online access for all operators

- Cloud-based solution with efficient data communication and open access for everyone

Value

- Increased system uptime – no waiting time for drivers

- Reduced downtime, idle time, and diesel consumption

- Improved production figures

- Higher production of washed gravel

- No manual entry of registrations

The ScanLoader System

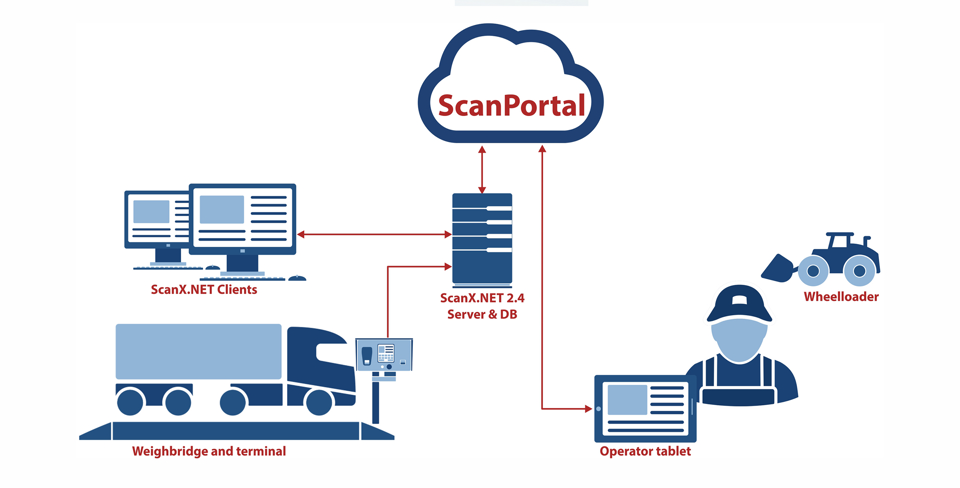

ScanLoader is a dedicated registration system specifically developed for the task of distributing raw materials from gravel pits. It is a cloud-based system designed for efficient recording of weighings and customer information, with data communication to the operator’s tablet or smartphone on-site.

Simple Process

Upon arrival, the driver registers on a PC using their ID and the product, after which the data is transferred to the operator’s tablet or smartphone in the wheel loader. This way, the operator knows exactly what the truck is to be loaded with and is prepared when the truck arrives. Once the truck is loaded, the driver logs out again on the PC. All recorded data becomes immediately available to the head office, which can access it through the cloud system for further processing and invoicing.

Positive Experiences

In Rødekro, Robert Thaler manages the gravel pit. He has been using the ScanLoader system since it was introduced in spring 2019 and shares his experience with the system:

“I am very satisfied with the new registration system, which has brought many improvements compared to the old system. It is flexible and easy to use, and it operates without downtime. With the old system, I probably spent 1–2 hours every day restarting it and troubleshooting issues. During a busy week with many trucks, that could add up to an entire day where I wasn’t operating the wheel loader — that corresponds to 20% of my working time, which I can now spend productively, such as loading trucks and washing gravel.”

Robert continues, “Now, with the new system, there are many weeks when I don’t have to go near the PC with the ScanLoader system — it just runs smoothly. And if any drivers have questions or need help with registration, we can handle it over the walkie-talkie.”

With the old system, I probably spent 1 to 2 hours each day restarting it and troubleshooting problems. Over the course of a week, this could add up to a full day — equivalent to 20% of my working hours, which I can now instead dedicate to loading trucks

Site Manager

Saving Working Hours — and Diesel — in the Gravel Pit

In Rødekro, the operation is busy with four wheel loaders handling numerous trucks and registering all weighings. This used to cause problems with the old system, where only one operator at a time could perform registrations — the other operators had to wait.

Robert explains further: “We couldn’t enter data simultaneously, and if the system went down, it cost us both valuable working hours and idle time on the wheel loaders, leading to unnecessary diesel consumption. That makes a significant difference since that downtime cannot be invoiced. However, the new ScanLoader system is flexible, allowing all of us to use it at the same time. And because the system now runs smoothly without problems or downtime, we save both working hours and diesel.”

Saving Working Hours — Also at the Head Office

The ScanLoader system has also saved working hours in administration at the head office in Tønder, says director Helmut Callesen: “Previously, we often had to spend time manually recording weighings here at the office. When the old system broke down, our wheel loader operators had to note all weighings on paper, which Yvonne here in the office then had to enter manually. We have completely eliminated that now, as she can access the ScanLoader system and retrieve all data directly into our administration system — which she can do whenever it fits into her workday.”

Higher Production Numbers

Robert manages the operation of the gravel washing plant, where he processes 34–35 tons of gravel per wash, taking approximately fifteen minutes. With the new system, he has freed up more time for this task, he says: “My production numbers are higher now than before. Since we avoid system downtime, I can probably fill the washing plant one or two more times during the day compared to previously. And as the plant washes 34–35 tons per wash/quarter-hour, this adds up to as much as 70 extra tons per day, which can be added on top of the daily production of 600–1100 tons of washed gravel.”

Open, flexible system

ScanLoader is a flexible system in several respects. For example, the driver does not need to register for each individual trip — which is an advantage when the truck collects multiple loads of the same product on the same day.

“Here, I simply make sure to register all loads and summarize the total weight in the system on my iPad once the truck is finished. The driver then receives a single weigh ticket for all loads,” explains Robert, finishing with a wink: “Of course, we only do this with those we know we can trust.”

The system is also open and flexible when it comes to creating new customers; a truck or customer does not need to be pre-registered in the ScanLoader system — the driver can register directly on the PC at the site during their first visit to the gravel pit.

With the ScanLoader system, Robert can also serve and load trucks that have not registered on the PC, but have come “around the corner” directly to him in the wheel loader — for example, a customer who only needs a single load of sand. As he explains, “Here, I can use a general customer number and just write the customer’s name and phone number in the comments field. When the head office later retrieves the day’s weight records for invoicing, they ensure that new customers are created with their own customer numbers for future use.”

Easy Correction of Input Errors

If a driver enters an incorrect product number during registration, Robert can easily and quickly correct it directly on his iPad from the wheel loader. “I simply pull up the driver’s registration on my iPad and change the number to the correct one. If I couldn’t do this on the iPad, the driver would have to perform a completely new weighing and register from scratch. So, we also save the drivers’ working time,” he says with a smile.

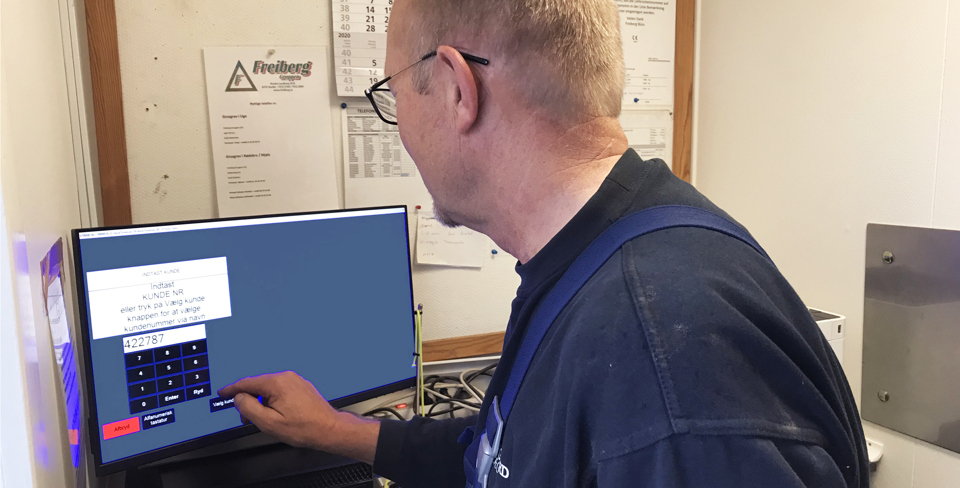

User-Friendly and Easy-to-Understand Operation

Both Danish and German trucks come to the gravel pit in Rødekro, so the registration system must be easy to understand. ScanLoader features a simple user interface that is easy to operate — even for new drivers, Robert explains: “We often experience that when a new driver who hasn’t used our new system before arrives, it’s easy for them to register for the first time — they just need to press the Danish or German flag, and the system clearly explains what they need to do. Previously, with the old system, there were lots of numbers and a page full of fields, which was quite confusing — especially for the Germans.”

Stable Data and Operational Reliability

If there are issues with a server being down or difficulty connecting to the internet, work at the gravel pit does not come to a halt. Robert can register weighings locally in the ScanLoader system on his iPad and then send them to the head office as soon as the server or connection is back online. At that point, Yvonne at the head office can forward the weigh tickets to the customers.

Read more about the related products here:

Contact our heavy duty experts

International Business Manager - Weighbridges

Sweden, Norway, Finland

+46 (0)70 630 54 60

Have a question? Request a callback