Software provides overview in metal scrap and saves working hours

Case Story: Bradals Product Trading

Bradals product trading is currently experiencing rapid growth and requires clarity on multiple fronts. The scrap company has achieved this with new software from Scanvaegt Systems, which streamlines workflows, provides flexibility, and increases profitability. Additionally, Bradal has contributed to the development of the digital solution.

Bradal is in the process of implementing new software, ScanClassifier, which modernizes workflows within the scrap company. The firm receives metal scrap from both commercial customers/trucking companies and private customers/individuals. In terms of volume, trucking companies account for 95 percent of all scrap delivered in Silkeborg, where the headquarters are located. However, by number of deliveries, private customers are in the majority and are paid immediately upon delivery.

Significant Time Savings

“Previously, registration was done manually — after weighing, our operator would write a note by hand with the weight information for the various metals delivered. The operator would then take the handwritten note to the office and hand it over to an accounting employee, who entered the information into the system and paid the private customer in cash,” explains Anders Holmer, who is the Finance Manager at Bradals Produkthandel.

This cumbersome manual handling process has now been replaced by the new software system.

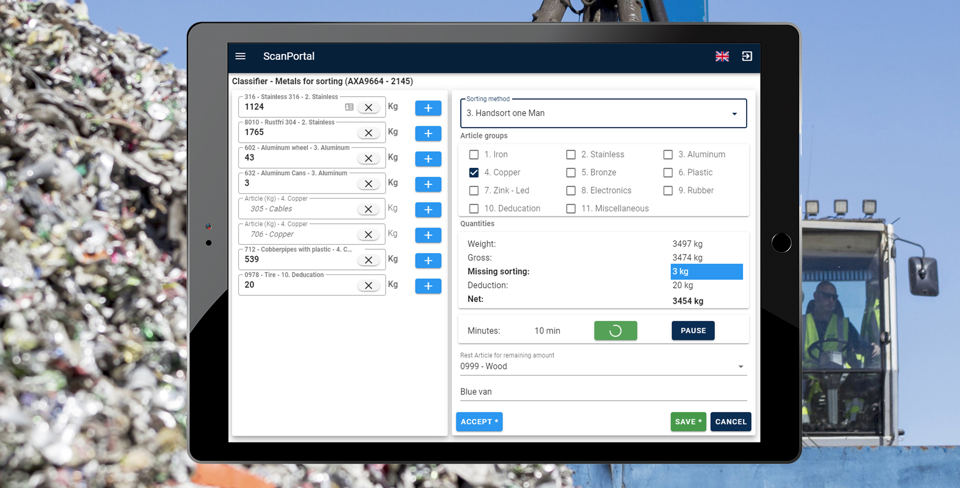

“With the new software, the operator registers information about weight and metal types on a handheld PC/tablet at the same moment the weighing takes place. These data are then automatically transferred to the accounting employee, who handles payment by transferring the money directly to the private customer’s bank account,” he explains.

According to Anders Holmer, the new handling process has created significant savings: “We have probably saved the equivalent of one full-time position, and those resources can now be used elsewhere. Additionally, we have reduced the risk of data entry errors, lost payment slips, and misunderstandings,” he adds.

Updated Inventory Overview Boosts Sales

For deliveries from commercial customers, the procedure is quite different. Handwritten notes and “all the interim calculations” are a thing of the past. As part of the new software, automatic license plate recognition is included. The system automatically recognizes and identifies trucks when they are weighed upon arrival and again when empty. It automatically creates a case with a specified amount of delivered tons of scrap, most of which is black iron.

Where the truck unloads the scrap, a flag with a number (which follows the order) is placed. As further documentation, the scrap quantity is photographed from various angles, and the times of the truck’s arrival and departure are recorded. The scrap is then sorted later.

“With the new ScanClassifier software, our handling has become more streamlined and efficient. This means, among other things, that our inventory is continuously updated so we know exactly what materials we have available for resale. After all, everything is sold onward,” emphasizes Anders Holmer.

We’ve likely saved the equivalent of one full-time position in that area, and we can now allocate those resources elsewhere. In addition, we’ve reduced the risk of data entry errors, lost payment slips, and misunderstandings.

CFO Bradal’s Product Trading

Increased Growth and Profitability

The ScanClassifier software from Scanvaegt System now enables hauliers to deliver their scrap—consisting of sorted, clean fractions—outside regular opening hours at both the Horsens and Fredericia facilities. Half of all the scrap handled by Bradal is delivered directly to these two sites.

“It is the activities in Horsens and Fredericia that have driven our triple-digit growth. And with the new software, we can realise this growth without hiring additional staff,” says Anders Holmer.

The idea for the new software emerged during a dialogue between representatives from Bradal and Scanvaegt System, aimed at developing and improving processes such as handling, workflows, and inventory management.

“We have not yet fully completed the system, but there is no doubt that we have already become significantly more competitive and profitable,” Anders Holmer points out.

In addition to the metal scrap sold from the facility in Silkeborg, Bradal has in recent years expanded its operations with sites at the ports of Horsens and Fredericia. In Fredericia, the site can accommodate up to 60,000 tonnes of iron, which is typically shipped to Turkish smelters, while copper, aluminium, and stainless steel are transported by truck to smelters in Germany. From Horsens, fractions such as stainless steel shavings are shipped to customers in Norway.

Bradals Produkthandel – A Family-Owned Business with Strong Traditions

Since its establishment in 1950, Bradals Produkthandel has received, recycled, and resold all types of metals—including scrap iron, new steel, copper, and more. Today, the company is run by the third generation, with Thomas Bradal at the helm. He took over from his father in 2003 and has since further developed the business, expanding both the physical space and the volume of metals handled.

Bradals Produkthandel follows a clear strategy to remain competitive: high quality, low operating costs, consistent product standards, strong environmental safety, direct personal contact, and outstanding service.

A key part of the operation is the massive scrap shear, capable of processing 35 tonnes of iron per hour. To keep it running at full capacity while minimizing costs, the company maintains a strong focus on optimizing workflows to ensure maximum operational efficiency and profitability.

Read more about the related products here:

Contact our heavy duty experts

Int. Business Manager - Weighbridges

Sweden, Norway, Finland

+46 (0)70 630 54 60

Have a question? Request a callback