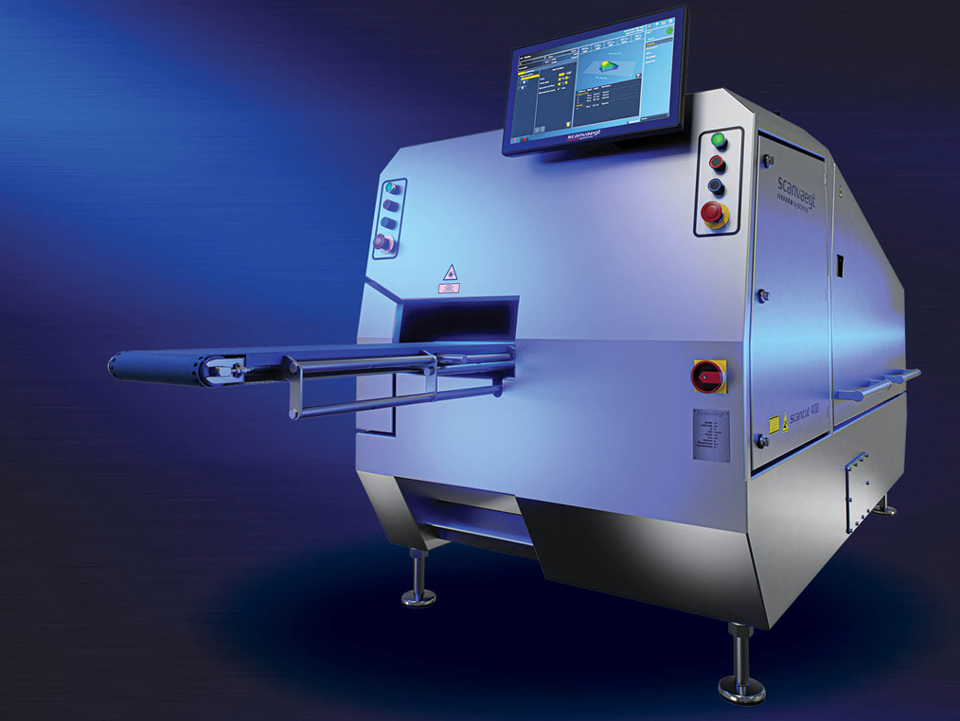

World Premiere: New ScanCut 400 Portioncutter

Designed for today’s food processing industry, the ScanCut 400 combines Advanced Blue Laser Scanning technology, high performance, and intelligent software to deliver optimal product yield and consistent quality – all in a compact and hygienic solution.

Significant benefits

- Precise fixed-weight portioning

- Reduced cutting waste

- Increased yield

- Consistent cutting quality

- Fast return on investment

- Space-saving compact design

- Compliant with strict hygiene standards

- Intuitive visual user interface

Precision Cutting for High-Value Products

The ScanCut 400 is purpose-built for portioning boneless, fresh fish and poultry into high-value, fixed-weight or fixed-size portions. With its advanced laser scanning and high-speed cutting system, it minimizes giveaway and maximizes yield – ensuring the best value from every raw product.

Maximizing yields with High-precision Blue Laser

Powered by cutting-edge blue laser scanning technology, the ScanCut 400 sets a new standard in accuracy and efficiency. Unlike traditional red lasers, the advanced blue laser minimizes surface scattering, delivering sharper, more detailed scans - especially on organic materials.

The result?

Minimal giveaway and maximized yield – ScanCut 400 guarantees exceptional results every time.

Flexible Cutting Applications

The ScanCut 400 supports a wide range of cutting programs tailored to different fish and poultry products. The system’s user interface displays a real-time 3D preview of the product and cutting pattern, allowing the operator to fine-tune performance and visualize expected yield before processing begins.

High cutting accuracy

The knife cuts with incredible high speed, which causes minimum impact on the product. Combined with a specially designed product holder, the system maintains product stability throughout the process, ensuring repeatable, high-quality results.

Tool-free knife angle adjustment

The cutting knife can be quickly adjusted to four predefined angles - 90°, 75°, 60°, and 45° - without the need for tools. This enables fast changeovers between product types while maintaining optimal cutting precision.

Userfriendly operation

The ScanCut 400 features a powerful multi-controller with a large touchscreen interface. Operators can easily select pre-programmed cutting applications, store new settings, and switch between products with just a few taps. Visual previews of the product and cutting patterns simplify setup and ensure production accuracy.

Durable, Hygienic Design

The machine’s robust and streamlined design minimizes product residue buildup and simplifies sanitation. All contact surfaces are food-grade approved, and the open structure supports efficient daily cleaning.

Thorough cleaning

For cleaning, the belts and knife-ring is loosened using grabbing handles. Cleaning is straightforward: with grab handles, key components can be loosened, detached, and rinsed. All water and residue are channeled to a central drainage point, making washdown fast and thorough.

Contact our food industry experts

International Business Manager

Automatic weighing systems

+45 4053 4900

News & Updates

New distributor in United Kingdom and Ireland

Scanvaegt Systems signs exclusive distributor agreement with Rolinson Group for United Kingdom and Ireland

Read more

New Strategic Parthership

As of May 1, 2025, Scanvaegt Systems A/S has acquired a majority shareholding in Bent Nygaard Elektronik ApS. This acquisition marks the beginning of a strategic partnership and represents an important step in Scanvaegt System’s growth strategy.

Read more

ScanPlant NG SeaPack Update

The ScanPlant Seapack System communicates with and transfers data to the new ELOG client version 14.0.

Read moreHave a question? Request a callback