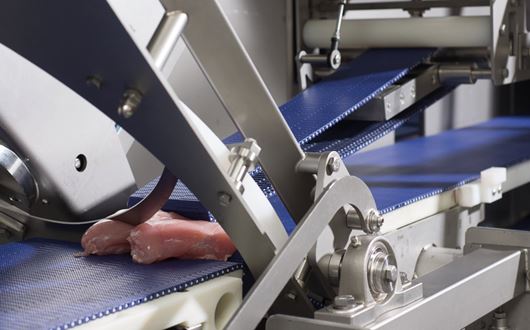

ScanCut 1A & 3A Portion Cutter

Cutting at an angle gives a natural look on sliced portions or a bigger plate coverage.

Designed to give a natural look on sliced portions, yet keeping the accuracy, the ScanCut 1A ScanCut 3A portion cutters allow the operator to change the cutting angle from 0° to 30° or 45° fast and easy, without the use of tools.

Combining state of the art technology for creating a high precision yet economic portion cutting machine, the ScanCut portion cutters are suited for fresh products such as poultry and fish fillets. The system can be configured with different product fixation systems and knife types best suitable for the product type.

The main difference between the ScanCut 1A and ScanCut 3A is the number of cameras; the ScanCut 1A has one camera and is suited for flat products whereas the ScanCut 3A has three cameras and is able to properly scan rounded products.

ScanCut 1A

The ScanCut 1 uses the laser camera from the top. A typical application for this portion cutter is chicken fillets that are portioned to a target weight and yet look as though they have been cut by hand from the breast caps.

The adjustment of the cutting angle is done without the need for tools and comes with the patented system that automatically adjusts the gap between the in- and outfeed belt to the optimum.

The ScanCut 1A can handle product sizes of up to 1000 x 240 x 150 mm.

ScanCut 3A

The ScanCut 3A has three cameras – one top camera and two lateral cameras. This allows the machine to improve the scanning and cover blind spots at the side of the product that cannot be detected by the top camera only. It is used for accurate portioning of red meat, whole fish or any product with an irregular shape, in a vertical direction.

The ScanCut 3A handles product sizes of up to 800 x 240 x 150 mm.

Both machines can be equipped with several options, which allows modifications to the ScanCut according to your evolving products and applications over the lifetime of the machine.

A product is fed on the infeed belt. A 3D laser-scanner then calculates its volume. A preset weight and shape frame is selected from the program menu. The portion computer then calculates where to cut.

A catch weigher can optimise the precision with changing product characteristics.

The machine can be opened up completely for easy cleaning and is designed for optimal cleaning to meet extreme hygienic standards (CIP integrated). The belts can be removed for separate cleaning.

For maintenance, easily obtainable spare parts have been selected. This guarantees lowest possible maintenance costs. All motors and encoders are situated away from the wet area, which ensures a long lasting lifetime.

Intelligente Funktionen

- High speed cutting

- Outstanding yield

- High precision

- Angled cutting

- Minimum give-away

- Labor-saving options

Sie haben noch Fragen oder möchten Sie weitere Informationen?

Dann füllen Sie bitte das nachstehende Formular aus.