Marelec Portio 3D

It is suited for fresh products such as tenderloin, striploin, rump, ham, schnitzel, etc. The system has different product fixation systems and knife types and is possible to adjust after product type.

A product is fed on the infeed belt. A three dimensional laser scanner then calculates its volume. A preset weight and shape frame is selected from the program menu. The portion computer then calculates where to cut.

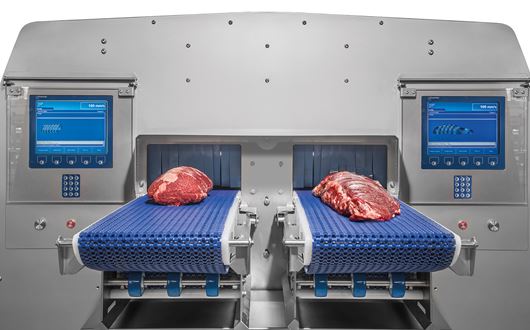

The highest possible throughput on the smallest possible footprint can be reached with the PORTIO 3D and its dual lanes. Each lane has its controller and the two lanes run completely independently from each other.

For most meat applications, one camera on the top is not enough to scan the whole product. In order to get a perfect view of the bottom roundings, it's necessary to have two cameras extra on each side of the belt.

Compared to the PORTIO 1DAP, the PORTIO 3D has got a wider belt of 300 mm, so it is able to cut products with dimensions up to 280 x 150 mm. All of this at the same capacity of up to 28 cuts per second.

A catch weigher can optimise the precision with changing product characteristics.

The machine can be completely opened for easy cleaning. The belts can be taken out for seperate cleaning.

SPECIFICATIONS

- Product dimensions: 800 x 280 x 150 mm

- Belt width: 300 mm

- Belt speed: adjustable up to 40 cm/s

- Cutting rate: up to 28 cuts/s

- 6 camera system: laser (top, left and right per lane) for highest accuracy on rounded objects (360° vision)

- Construction: stainless steel AISI 304 and FDA approved food plastics

- Conveyor belt: modular type

- Separate infeed belt

- Inclined surfaces

- Selections keyboard: IP67 with integrated electronics

- Indicator: UTP TCP/IP-connection

- Power supply: 3 x 400 V + N / 50-60 Hz / 12 kW

- Air supply: 6 bar, 50NL/min for air dryer

- Cleaning: designed for optimal cleaning to meet extreme hygienic standards (CIP integrated)

- Software: MARELEC P1 intelligent optimisation software

- Connectivity: internet direct connection for remote flexible servicing

OPTIONS

- CW2: manual infeed check weigher

- MC3: grader for fixed weight packages

- APH: Automatic Product Holder

- BH: Back Holder

- FH: Front Holder

- OPH: Outfeed Product Holder

- RO: Retractable Outfeed

- Auto clean: electro valve for separate cleaning of belts

- Multitap transformer / Power supply (UL approved)

- MARELEC C-PORTIO software: to generate production reports and trace program changes

- Knife sharpening device

Intelligente Funktionen

- High speed cutting: Fixed weight, fixed thickness

- Outstanding yield: high precision, minimal give-away

- Dual lanes: Highest throughput on smallest footprint

- 3 cameras per lane, 6 in total: Perfect scan of round products

- Flexible software

- Easy to clean

- Labor saving options

Specifications

Sie haben noch Fragen oder möchten Sie weitere Informationen?

Dann füllen Sie bitte das nachstehende Formular aus.