Dedicated packing solution for meal boxes

Offering meal boxes of various content, sizes, number of days and dishes may put heavy demands on the packing line.

Meal boxes is easy solution for the busy family and the sales are growing steadily. The meal boxes are tasty, healthy, fast, inspiring and at the same time help to reduce food waste.

The producers offer meal boxes of various content, sizes, number of days and dishes, so many types of boxes have to be packed. This may put heavy demands on the packing line.

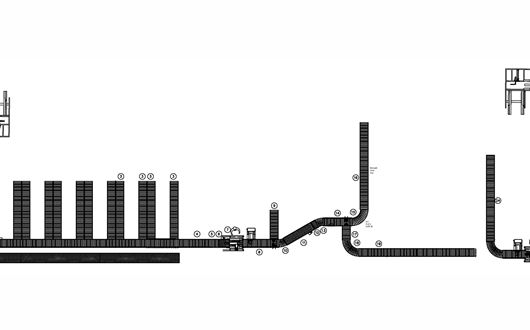

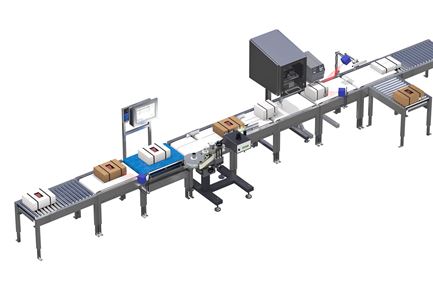

Scanvaegt has developed a dedicated solution with both hardware and software for managing, packing and shipping the meal boxes. Product Manager Allan Hedevang explains; “We have designed a solution specifically for packing meal boxes that handles the entire process from case erector to shipping. The solution consists of a packing line, which transports the empty box on to a number of packing stations, where the operators put the food and ingredients in the box. Then the box is passed on to the case sealer and label printer with an applicator that automatically prints and applies the address label”.

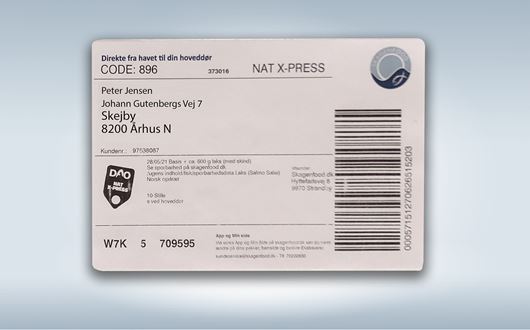

The solution has several integrated control functions, which prevent incorrect marking. Allan Hedevang explains the details; “The barcode contains the trace number and is automatically quality checked by a barcode scanner. At the same time, the number is checked against the most recently printed, preventing print of duplicate labels. In case of errors on the box, it is automatically rejected by an integrated pusher onto a separate conveyor. This ensures correctly labelled boxes and eliminates spending working hours on repackaging and shipping errors”.

The entire packing line is operated by the ScanPlant MES software. This system downloads packing orders from the company's ERP system and displays the orders of the day on a pt9000 computer terminal at the packing line. Here the operator selects the individual order for packing and starts the process.

“At the pt9000-terminal, ScanPlant shows a list of all orders and the number of meal boxes per order so that the operator has a complete overview of today's production,” explains Allan Hedevang and continues; “It could for instance be the order for the "Favourite box” for 254 customers, which is then packed by the operators at 7 packing stations. The boxes are then automatically labelled with an address label, which in addition to the recipient, trace number, content etc. also indicates whether the box is to be sent to Eastern Denmark or Western Denmark. When the order packing is completed, the ScanPlant system automatically reports back to the ERP system. It provides fast processing and invoicing, and reduces manual errors in order processing ”.

The packing solution for meal boxes automates a number of tasks and digitises several processes, which saves a lot of time. At the same time, the quality control prevents incorrect labelling of the meal boxes, so that returns are avoided.

Skagenfood is one of the suppliers of meal boxes that uses the Scanvaegt packing solution.

Read more about Skagenfood here (article in Danish): https://www.food-supply.dk/article/view/816270/succesen_i_strandby?ref=newsletter&utm_medium=email&utm_source=newsletter&utm_campaign=daily