Improved profitability on the Packaging Line

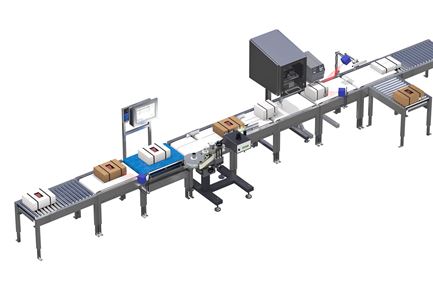

Scanvaegt Systems is a leading supplier of end-of-line systems for packaging departments and can provide a fully-automatic, scalable solution for the entire line. All processes - from weighing, labelling and quality checking - can be run automatically through the line with no manual handling.

For decades, Scanvaegt Systems have been providing advanced packaging solutions for the meat, fish and chicken industries. Scanvaegt offers a wide range of different EOL solutions, including both hardware and software. ‘EOL’ is an abbreviation of ‘End-of-Line’ and refers to that element of packaging that begins where the packaged product is weighed, labelled with all the relevant information and checked.

Poul Thisted, International Product Business Manager, has been working in the field of EOL for 30 years. In this article he looks at weight checking and flexible labelling systems; “Our customers often contact us when they are looking for ways to optimise their packing processes. They usually wants higher capacity, automisation and reduction of manual handling to avoid typing errors and zero data errors, traceability and particularly workforce savings,” explains Poul Thisted.

The customer is also very interested in the payback period for a EOL solutions, which is often less than a year. According to Poul Thisted, this is due to the fact they can often reduce working hours corresponding to a full-time position per step in the various EOL processes – compared to a 10-year-old packaging plant.

Automated solutions for weighing and labelling

Scanvaegt can provide a number of different automated EOL solutions, including weigh price labelling systems that are used for weighing and labelling retail packages in the first process of the packing department. This system combines two functions.

Poul Thisted explains; “The system first weighs the individual package and then prints a label with information about weight, date, batch number and bar code and applies the label onto the package. If the package is over or under preset weight tolerances, it is automatically rejected out on a separate belt, so packages with the wrong weight are not shipped to the end-customer.” He goes on: “This wpl-system is the Formula 1 model and has a maximum speed of 120 items per minute, which makes it one of the most efficient and dependable systems on the market.”

In the next packing process the packages are packed in the boxes. “Once the box has been packed, it has to be sealed, weighed and labelled. For this purpose, Scanvaegt offers the ABWL system (automatic box weigh labelling), an automated solution that ensures increased packaging flow,” says Poul Thisted. “Our ABWL solutions can handle several different box types and sizes on the same line. Using the product ID Code, the system makes a pairing check of the box. This ensures consistency between the products in the box, the data on the label, the weight content and the traceability label. If there is a discrepancy, the carton is automatically rejected.”

Together with a major Danish slaughterhouse, Scanvaegt has developed a special ABWL concept. This scalable concept is capable of automatically handling different box types and sizes on the same conveyor system; “The slaughterhouse thereby reduces labour costs considerably. Previously, they had to have an employee at each weighing station to select the item number based on manual assessment,” explains Poul Thisted.

To ensure efficient, smooth traffic on the packaging line and prevent production stops, Scanvaegt has developed a solution that ensures that there is only one box per conveyor belt module. This allows the speed to be increased up to 20-30 boxes per minute with correct labelling guaranteed. The solution can also handles stops on the line and prevents package build-up.

At the final process in the packaging department, the Scanvaegt solution automatically labels the pallet with the boxes with SSCC labels on two or three sides and, if required, at different heights. The system can also check the readability of the barcode on the label and ensure that it can be read by barcode scanners when it reaches the customers.

Digitisation creates a higher bottom line and stronger competitiveness - ScanPlant NG MES

What all the different EOL processes have in common is the software that ties it all together.

Scanvaegt has a highly efficient tool for production management – ScanPlant NG – a manufacturing execution system for managing and planning all processes from goods reception to production, packaging, stock management and shipping. In the packaging department, ScanPlant handles controlling jobs such as metal detection, weight checking, weight price labelling, box labelling and pallet labelling.

Poul Thisted explains in details; “We are one of the few suppliers to tackle all production processes with our ScanPlant it-system, that enables the customer in monitoring production development and creating transparency in everything from productivity and inventory development to yields and give-away in real time. Data capture = increased revenue.”

ScanPlant also enables the client to cut back on workflows and reduce sources of error: for example in the automatic order processing; “The interest for our ScanPlant solutions is increasing,” says Poul Thisted, “It is a unique tool that can also provide small and medium-sized food companies with valuable improvements - even a small business can reduce working hours corresponding to a half-time position, which reflects directly on the bottom line. So, investing in a new EOL system creates higher earnings and improves our clients’ competitiveness.”

“When it comes to automation, the food companies we work with are leading the way - and that includes several medium-sized companies. They all know that optimised production processes leads directly to increased revenue,” concludes Poul Thisted.