Come visit us at Anuga Foodtec in Cologne

Solutions for digitizing and automating the packaging processes.

At Anuga Foodtec in Cologne, you can experience dedicated solutions at our booth B108 in Hall 10.1, where we'll be presenting the SB520 ScanBatcher, Scanvaegt WPL weighing and labeling solution, and ScanPlant NG Manufacturing Execution System.

Scanvaegt SB520 ScanBatcher: The sustainable solution

The SB520 ScanBatcher is the next-generation weighing machine for tolerance batching, minimal batching, and simple sizing.

At the same time, it represents a sustainable solution for replacing an existing Scanvaegt 7100 or 4700 - you can limit yourself to replacing the weighing machine and continue working with the existing separator and feed section. This supports UN Sustainable Development Goal 12 and significantly reduces both installation time and investment by at least €50,000.

Furthermore, the ScanBatcher SB520 is a highly precise solution that minimizes give-away to an absolute minimum and maximizes the potential yield from raw materials. This can be seen directly on the profit and loss statement.

ScanPlant NG MES: Improves the production process - increases profit

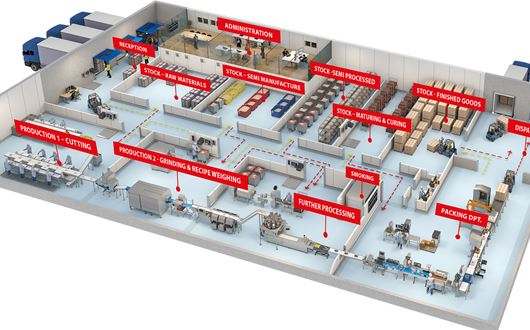

ScanPlant NG Manufacturing Execution System is an excellent tool for real-time monitoring and optimizing productivity, inventory development, yield, and give-away.

With ScanPlant NG Yield Control, you ensure that even small deviations in individual processes are detected. This allows you to take preventive measures, reduce give-away, and avoid high yield losses.

The captured data from goods receipt, warehouse, production, and shipping form the basis for automatic key figures and KPIs in real-time. You have an overview, can check things faster, and intervene if necessary, improving profit potential.

ScanPlant NG WPL: Intelligent and efficient Labelling

ScanPlant WPL is an intelligent software system that ensures that the products are labelled with the correct informations, e.g. product content, ingredients, storage instructions, shelf life, EAN and GS1 barcodes.

The system registers all of the traceability data through all production processes and has an automatic function for data-summation, which gathers data for the next packaging level – from item to box and from box to pallet. The system also manages data about the origin of the product and lot number for the traceability of the individual products.

Scanvaegt WPL packing station

This compact unit represents one complete system with hardware and software for weighing, packing and labelling retailpacks and similar products in an easy and efficient manner.

The sturdy frame integrates bench scale, labelprinter, scanner and the pt9000 computer terminal with the ScanPlant NG WPL system. All products are designed for use in the harsh industrial environment.

The ScanPlant WPL system makes product labelling management easy and has several strong features, e.g. automatic data summation for the final label, freely editable label designs, full traceability management and package weight control

Scanvaegt industrial bench scales

On display are also the Scanvaegt series of industrial bench scales which are produced in stainless steel specially designed for use in the industry and are built to withstand rough treatment.

So, drop by our booth# B108 in Hall 10,1

We look forward to meeting you and learning more about your production.