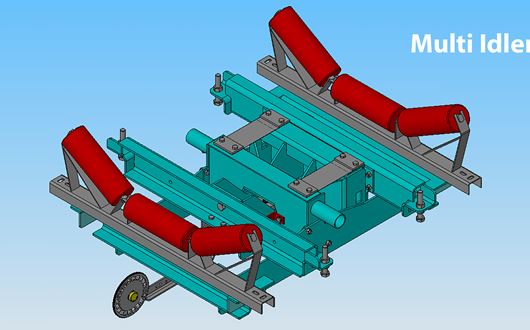

Multi-idler belt scales:

Multibelt® BMP is an dual-idler belt scale for feed rates up to approximately 15,000 t/h, whereas Multibelt® BMC is a multi-idler belt scale for feed rates up to around 20,000 t/h.

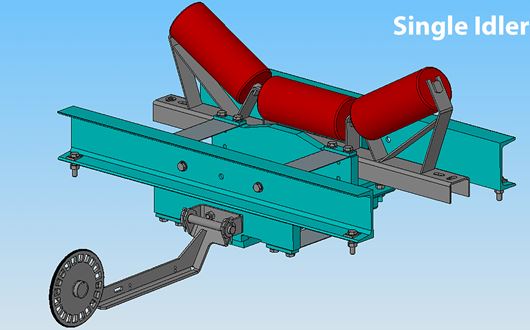

Single-idler belt scales:

Multibelt ® BEM is a single-idler belt scale for feed rates up to approximately 4,000 t/h, whereas Multibelt® BEP is a single-idler belt scale for feed rates up to around 6,000 t/h. Finally, Multibelt® BED is a single-idler belt scale for feed rates up to approximately15,000 t/h.

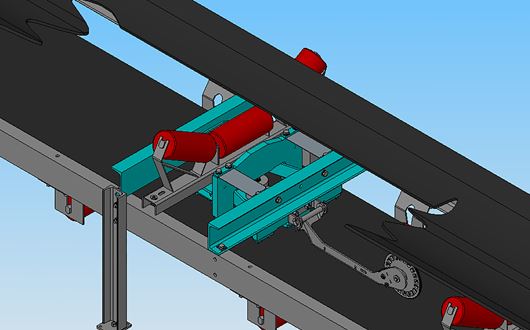

Flexible and maintenance-free:

Whether using standard belt widths of 500 to 2,000 mm or a customised belt width beyond normal IEV belt widths, Schenck can provide the right solution for every application – solutions that are easy to plan, integratable and maintenance-free.